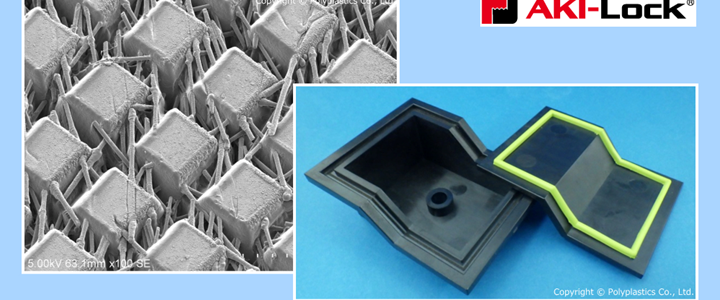

An innovative bonding technology for glass fiber reinforced thermoplastics from Polyplastics Co. Ltd., is said to be unlike traditional joining methods such as plastics welding or adhesion. Aki-Lock has few restrictions on the materials that can be used and reportedly forms strong, airtight bonds with combinations of different materials for which bonding had previously been difficult. This bonding technology is said to open the door to a broad range of new product development possibilities. It meets the increased market demand for weight reduction to address Sustainable Development Goals (SDGs), reduces the number of parts, and provides stable adhesive strength and longevity, according to the company. Aki-Lock uses the glass fibers in glass fiber reinforced resins as a physical anchor for bonding. Glass fiber is made bare by laser irradiation which is completed in a grid pattern. Strong bonds can then be achieved by pouring the resin to be bonded onto these anchors. Since the bond is formed by physical anchors, there is no time limitation from laser treatment until bonding. Masking is unnecessary since specific treatment areas can be identified. There is no need for etching solution to roughen the surface and no waste liquids or materials are produced. Airtightness is greatly enhanced due to three factors: the effect of resin entering and filling the gaps between the glass fibers; deformation in the grooves of the primary material due to the shear flow force of the secondary material; and crimping from mold shrinkage of the secondary material. Aki-Lock helps to reduce assembly work and the number of components, thus lowering overall cost. The joining system also helps to reduce environmental impact through the use of dry processes, including the elimination of adhesives.