From the

viewpoint of environmental benefits and cost reduction, thermoplastic

vulcanizates (TPV) have been widely used in many industrial

applications, particularly auto motive weather seal applications. The

adhesive properties between TPV and cured rubber are important in this

situation. In this paper, we studied the factors contributing to the

adhesion between TPV and cured rubber, and report about a new advanced

Excelink TPV with excellent adhesion properties. 1. Introduction Thermoplastic

vulcanizates have been widely used in automotive applications due to

environmental benefits and cost reduction in the production process.

Environmental benefits include weight reduction, recyclability, safer

curing agents (no nitrosamines), energy saving in process, etc. Cost

reduction is given by its much simpler process and higher productivity

than cured rubber. TPV technology has been recognized for enhancing

productivity and performance. Excelink

TPVs, based on ethylene-propylene diene rubber (EPDM) and polypropylene

(PP), have been developed since the year 2000 as advanced materials

mainly used for automotive weather seal applications worldwide, such as

glass run channel corners, door seal corners, drip seals, end caps, body

welds, etc. Excelink TPVs are characterized by their morphology. 2. Key factors of adhesion As

mentioned above, weather seals using TPVs for the corner parts and EPDM

for the straight parts can be produced by insert molding. At this time,

TPVs and dense EPDM are bonded by thermal fusion bonding. What is the

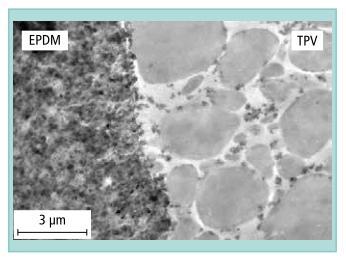

key factor of adhesion between TPVs and dense EPDM? The TEM micrograph

in figure 2 shows the adhesion interface of the TPV and the EPDM. As shown in this figure, it is confirmed

that the PP phase exists at the EPDM/TPV adhesion interface.

Considering the above, the adhesion of a TPV and dense EPDM seems to be

influenced by three factors: • Properties of the PP • Morphology of the TPV • Surface condition of the cured dense EPDM. Details of the three factors are described in the following. figure 2 2.1 Properties of the PP In

this section we investigate the effects of the properties of the

poylpropylene, such as the crystallinity and the moleculer weight, on

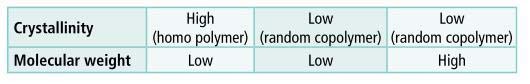

the adhesive characteristics. Table 2 summarizes the sample details.

Here, specimens are prepared by insert molding of PP and dense EPDM. The

morphology of the inter-face between the PP and the EPDM is observed by

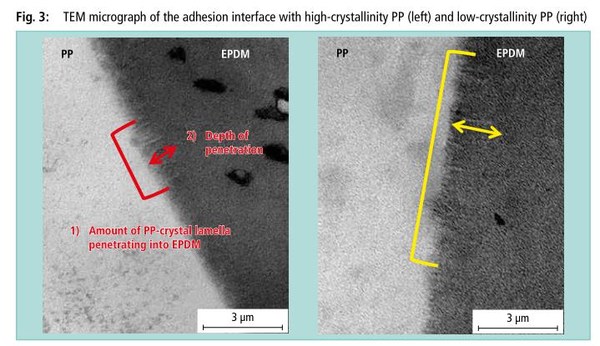

TEM. Figure 3 shows the effect of the crystallinity of the PP on the

morphology, where the dark area means the EPDM phase and bright area

means the PP phase. It is indicated that the crystal lamellas of PP

penetrate into the EPDM. Moreover, it is found that the crystallinity of

the PP affects the amount of the crystal lamella and the penetrating

depth into the EPDM. Low-crystallinity PP shows a larger amount of

crystal lamella and deeper penetrating depth than high-crystallinity PP.

These results suggest that in an insert molding process the molten

low-crystallinity PP penetrates deeper into the dense EPDM than

high-crystallinity PP. Table 2 To

sum up, low-crystallinity PP can penetrate into the cured EPDM more

easily than high-crystallinity PP, which provides higher adhesion.

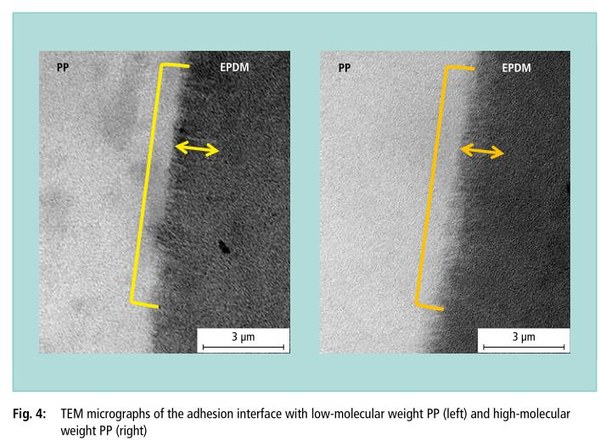

Figure 4 shows the effect of the molecular weight of low-crystallinity

PP on the morphology. The penetrating depth of the crystal lamella does

not depend on the molecular weight of the PP. On the other hand,

entanglement of PP molecules tends to increase with increasing

molecular-weight. This result suggests the increase in entanglement of

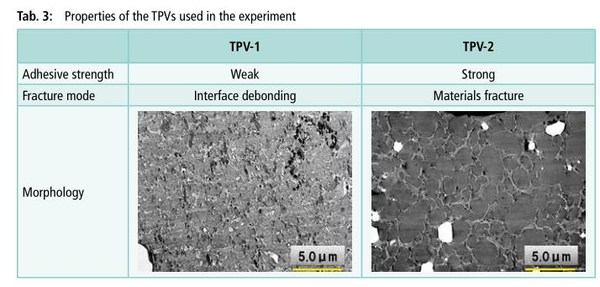

PP allows the strong adhesion to the cured EPDM. 2.2 Morphology of the TPV The

effect of the morphology of TPV on the adhesive characteristics is

investigated. Table 3 summarizes the sample details. TPV 1 shows a

coarse dispersion of EPDM particles, and the adhesive strength is weak.

TPV 2 shows a finely dispersed morphology, and the adhesive strength is

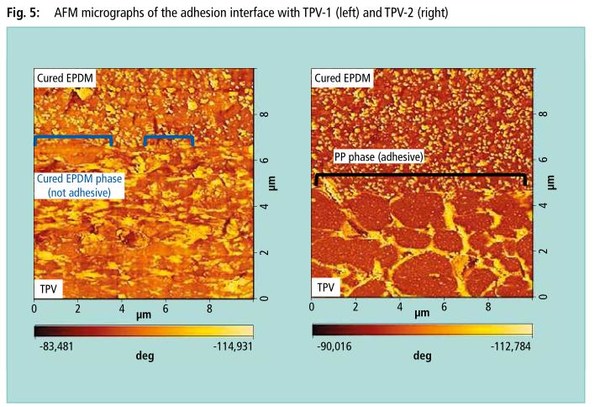

strong. To investigate the effect of the TPV morphology, we observed the

interface between TPV and EPDM by AFM (fig. 5). From the AFM micrograph

it can be observed that the TPV is adhered to the cured dense EPDM

through the PP phase on the interface. It is found that the adhesive

area of TPV-2, which has a finely dispersed morphology, is larger and

much more uniform than that of TPV-1 having the coarse morphology. This

result indicates that a uniform and finely dispersed TPV morphology can

provide an increased adhesion in the area of adhesive PP phase between

TPVs and cured EPDM interface. Therefore, TPV-2 shows higher and more

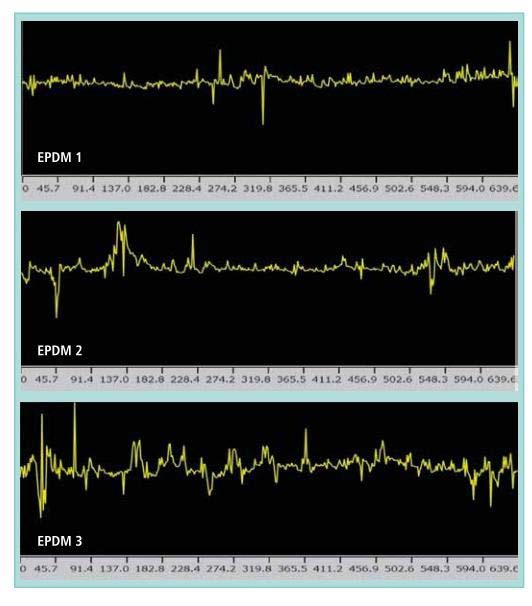

stable adhesion characteristics. 2.3 Surface condition of the cured dense EPDM As

mentioned above, the surface of the dense EPDM is smoother than the

surface of cured EPDM sponge. In this section we investigate the effect

of the surface roughness of the EPDM on the adhesive characteristics.

Figure 6 shows the surface profiles of the EPDM used in the experiments. 3. Results We studied the factors contributing to the adhesion of TPV and cured dense EPDM. As a result, it is confirmed that the following points are important to improve the adhesion strength between the TPV and the EPDM •

Crystallinity and molecular weight of PP The molten low-crystallinity PP

penetrates deeper into the cured EPDM phase, and also the increase in

molecular of PP leads to the strong adhesion with the cured EPDM • Morphology of TPV The finely and uniformly controlled morphology of TPV increases the adhesion area with the cured EPDM dense. •

Surface roughness of cured dense EPDM The increase in the number of the

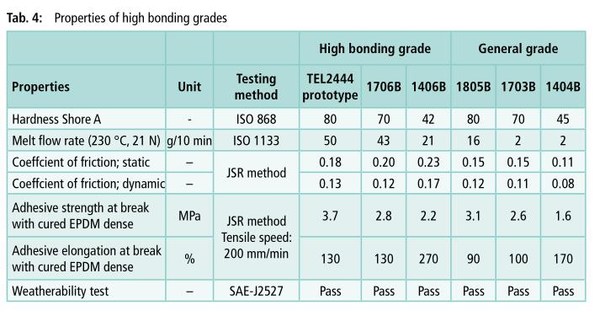

pores in the EPDM surface improves the physical anchoring effects. Based

on the results of this study, we have developed Excelink TPV grades

with optimized bonding properties to EPDM. There is a three grades

line-up with hardness from 40 – 80 Shore A available. Table 4 summarizes

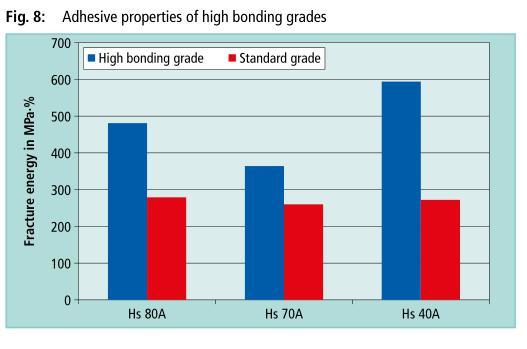

key properties of these grades. Figure 8 shows the results of the

adhesive test with cured dense EPDM. Adhesive properties of high bonding

grades are better than those of general grades. Regarding the melt flow rate, the new high bonding grades provide a much higher melt flow

rate than conventional grades. Consequently, the new high bonding

grades may be preferably used for complex parts and parts requiring good

adhesion to cured EPDM dense, such as automotive weather seal

applications. Source: TPE magazine